Inspections - Maintenance - Repairs - Equipment Instalations

1. Description: Based on more than 60 years of proven experience as a designer, manufacturer, installer and supervisor of start-ups and start of operation of our equipment and systems in the national and international market, Lapsolite has developed based on these experiences and the incorporation of methodologies; such as the method of Kepner Tregoe, cause analysis from the root, 5's methodology, total productive maintenance (TPM) and the cycle of Deming (PDCA circle). The company also offers programs and planning that include post-sale of equipment systems and processes, becoming partners in business with partnership programs offering maintenance services, inspection, repair, removal and installation of systems and equipment.

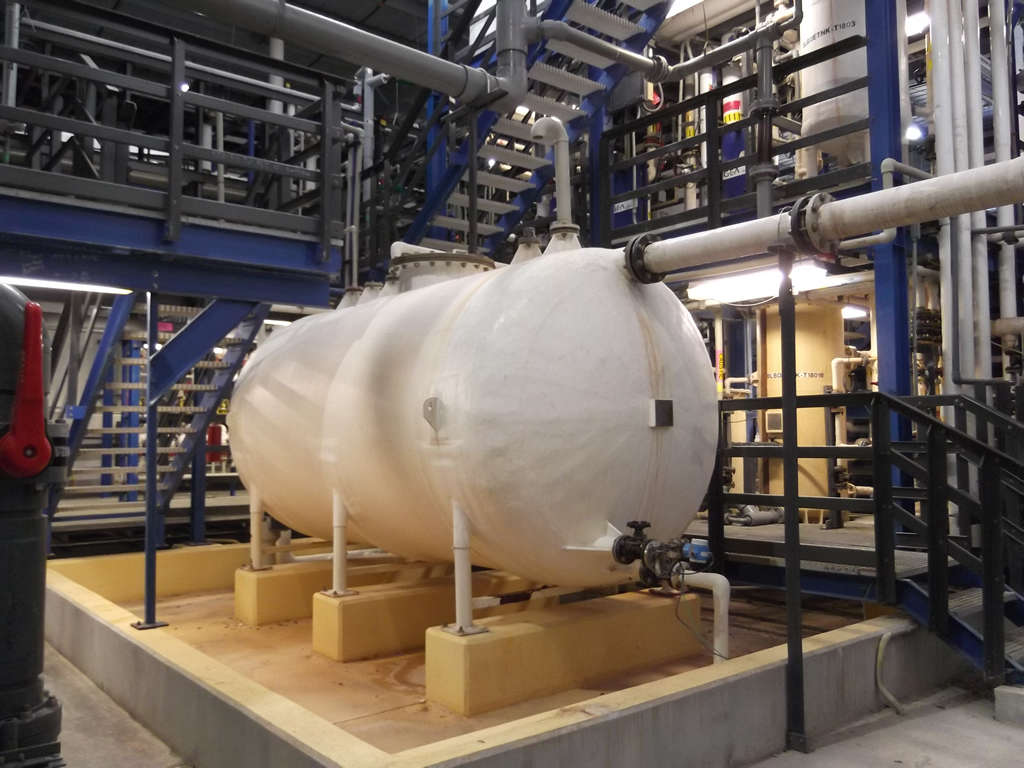

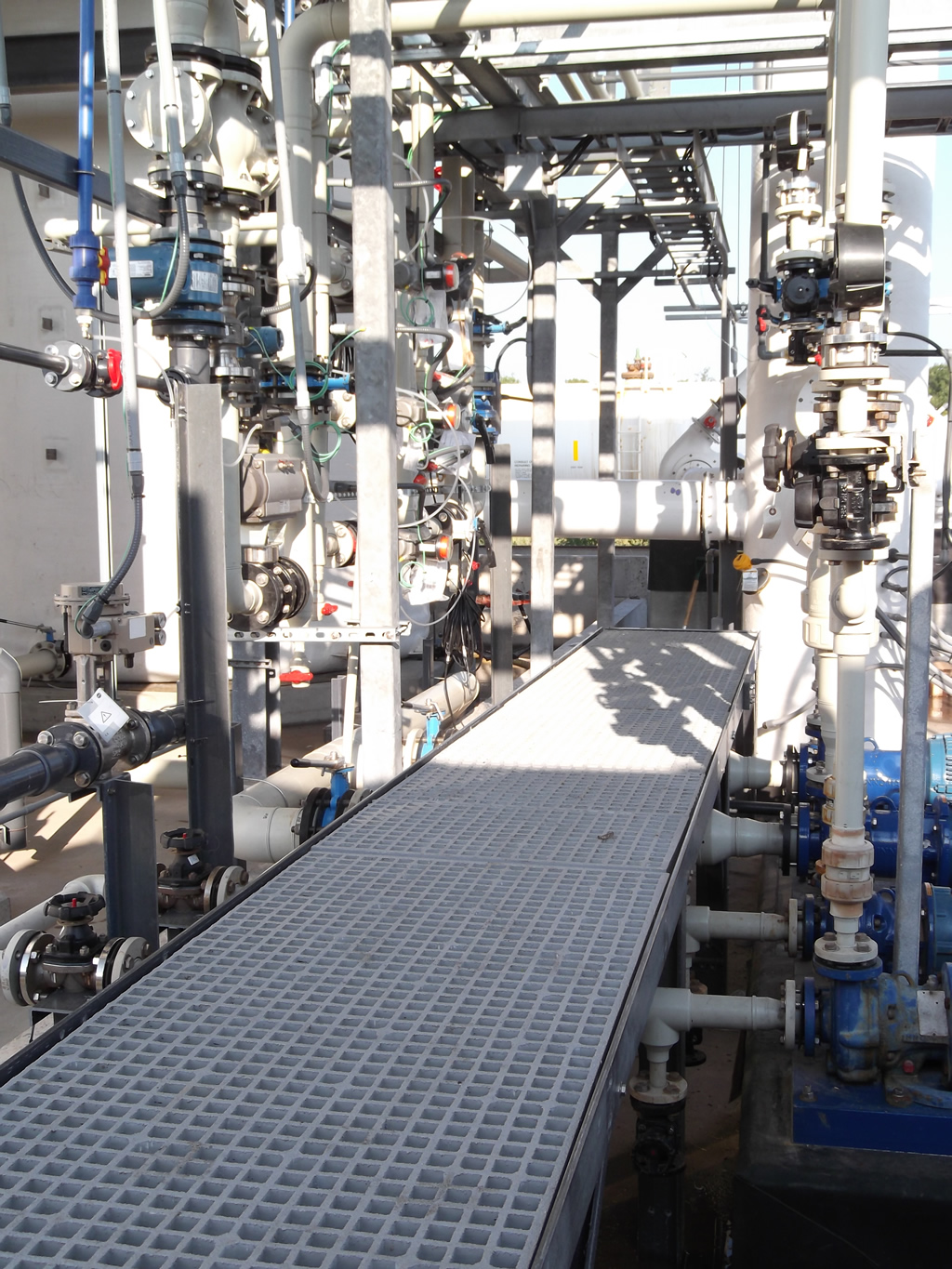

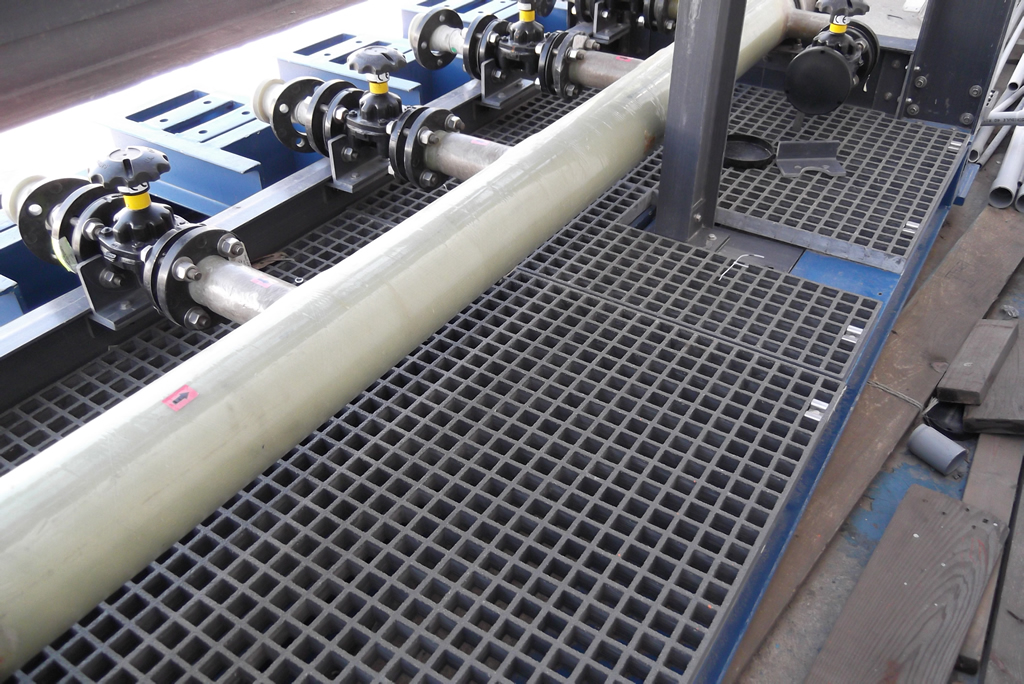

2. Ranges of application: within the services we offer, we deal with the execution of policies of inspections, maintenance and repair to any type of industrial equipment manufactured in fiberglass and thermoplastic materials or both, known as double laminate equipment. For this type of work Lapsolite guarantees all work in these areas; the warranty time is based on a preliminary analysis of root-cause to detect the reason for the possible failure or wear and offering the best technical-economic alternative for our customers. Repairs offered include:

- Tanks and storage stations

- Cooling towers and cooling systems

- Injection - gas extraction systems, fans

- Systems of ducts and pipes for gas and liquids

- Washing and photocatalytic air systems

- (WWTP) water treatment and peripheral systems

3. Benefits:

a. Low investment cost vs new equipment.

b. Less time wasted on line shut-downs.

c. Repair time according to the kind of repair.

d. Minimum one year warranty on repairs.

e. Enforcement of regulations and laws.

ENGLISH

ENGLISH